Mod Pump

- admin

- September 22, 2022

- 6:34 pm

Pumps are used for many critical things, from home appliances to large-scale industrial and commercial equipment. In fact, pumps are used in so many things that there is almost an unlimited amount of sizes, styles, and designs.

With so many equipment options, it can be time-consuming and challenging to find the right replacement if your pump fails, whether at home or on the job. Or, what if the pump in your current appliance isn’t doing the job, and you need to replace it with a pump with more horsepower? Simply looking at dozens of options and comparing them can easily take all day.

The Mod Pump – Innovative Design For So Many Applications

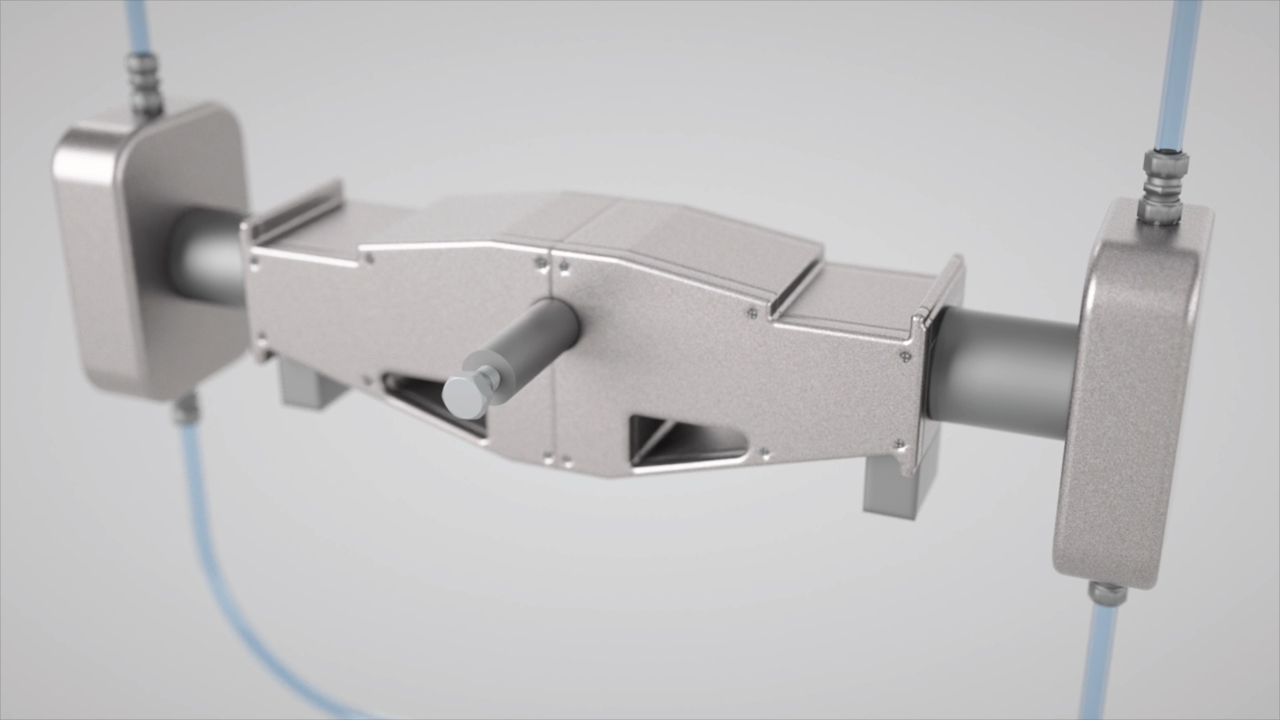

Customers, from home appliance repair companies to large-scale industrial clients, seek a smaller, more compact, and lightweight design but with higher flow. Nothing on the market fit all of these needs until the Mod Pump – a new mechanical pump with an innovative Mod design.

How the Mod pump’s design sets it apart from other types of commercial and industrial pumps:

• The center-mounted crankshaft has two connecting rods on one journal

• The crankshaft drives two reciprocating-style pumps set horizontally 180 degrees apart

• Each reciprocating pump has an independent fluid end

• Compact design reduces the size and space required to install

• Dual pumps decrease replacement costs

• Mod pump is available in multiple sizes for different applications

Advanced Features Make the Mod Pump a Versatile Tool For Any Pump Need

Like other pumps, the Mod pump is available in different sizes to fit your various needs. The difference between this new design and other traditional industrial pumps lies in the center-mounted crankshaft with two connecting rods on a single journal. The center-mounting of the crankshaft and balanced rods on either side reduces the width of the pump, fitting more applications. And, the design also reduces vibration, which means less wear and tear on the other parts of the machine.

The redundancy of the design is also a step up from other commercial pumps. If one fluid end fails, you simply replace it, instead of needing multiple-end replacements. Sincethe Mod pump has independent fluid ends; replacement costs are less if one end goes out. And, if you need extra GPM for your job, you can use a splined crankshaft with a male and female end to stack the Mod pump units side-by-side, with multiple Mods and higher flow, while still only requiring one drive motor. Again, another cost-effective feature of the Mod pump.